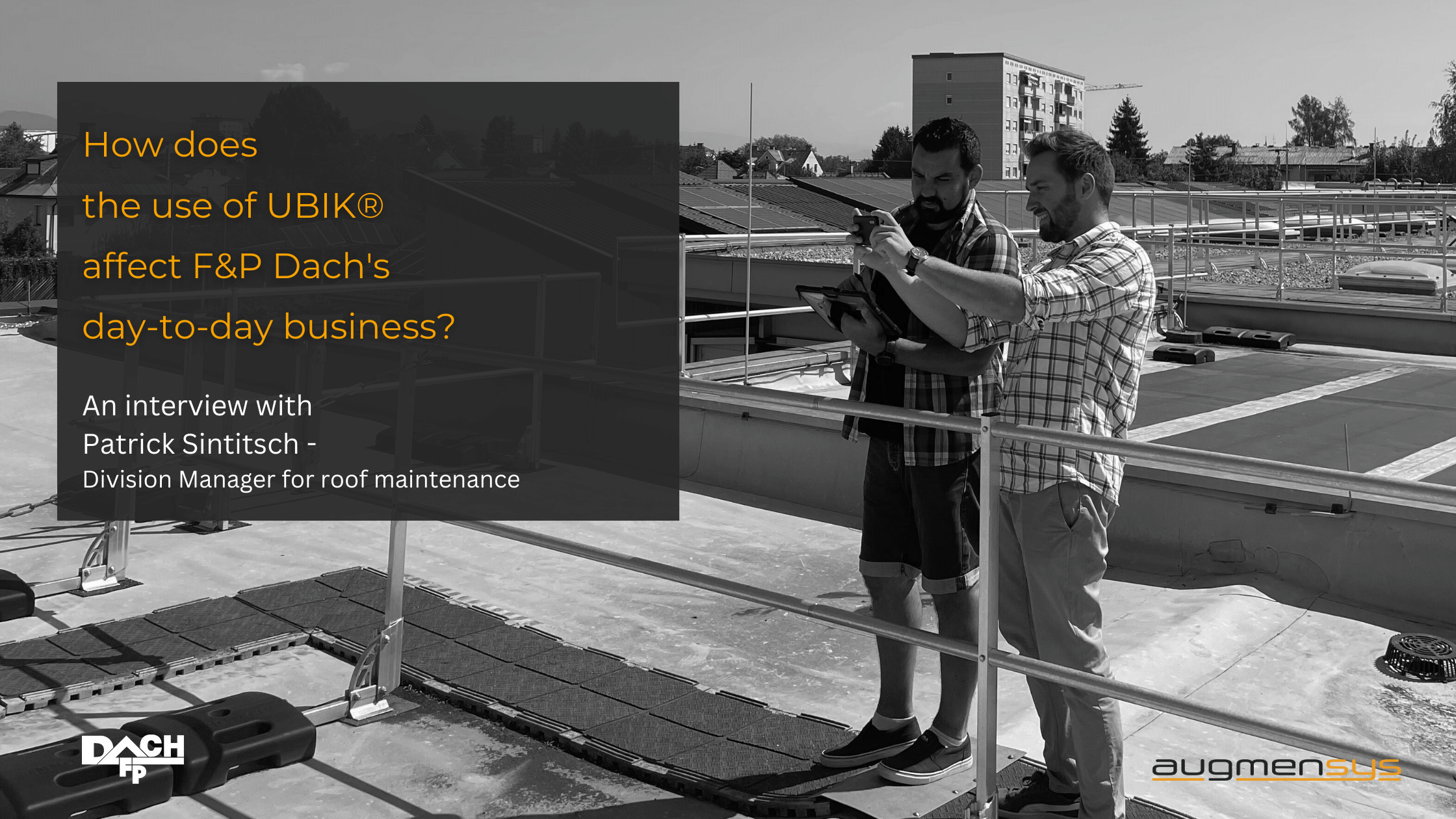

Why did F&P Dach decided to work with Augmensys?

As Fleischmann & Petschnig, we were looking for a reliable partner to digitalise our roof maintenance and roof inspection processes.

How long have you been using our UBIK software for roof inspections?

We have been live and operating with Tele-Roofing since 2017.

Which projects have already been realised with UBIK?

Basically, we cover all roof maintenance in the Tele-Roofing programme.

This ranges from existing customers, where regular maintenance and repairs take place, to new customers where a complete survey of existing or newly installed roofs takes place.

Are there any particular features or aspects of the software that are particularly helpful for your requirements?

We are currently focussing on the Xamarin mobile application, as it allows our employees to carry out their daily work more quickly. We particularly like the quick handling of the photo documentation, especially when recording damage.

What do the roofers say about UBIK?

The Tele-Roofing application is very helpful for our employees. Of course, switching from existing processes to new ones is always difficult and bumpy. But thanks to constant adjustments and improvements, everyone is satisfied.

How does the use of UBIK affect FP Dach’s day-to-day business?

Thanks to new assessment systems such as the traffic light system for roofs, where the entire partial areas are classified according to a traffic light system based on their condition, we can react faster and present our customers with solutions and measures more quickly in order to avoid further damage or to be able to give our customers a clear statement as to whether their roof is already in need of renovation or not. These analyses of the inspection reports are then discussed with the customer following the roof maintenance in order to discuss the best possible measures with them and save costs at the end of the day.

How easy was it to integrate our software into your existing processes?

The start was very mixed and sceptical. Our employees were used to carrying out roof maintenance manually. When introducing a digitalised roof maintenance tool, there were a lot of questions regarding additional work or simplification of processes. After targeted training and discussions with our employees, it quickly became clear that this would make work much easier for our employees on site.

Was there a need for training for your employees to use the software effectively?

There is actually a constant and ongoing need for training.

Especially with regard to the constant innovations that are intended to make work easier for our employees.

Can you share specific examples of positive results or experiences that have resulted from using UBIK?

The office can now analyse roof maintenance much faster and react quickly to major deviations. As a result, the customer can count on results much more quickly and can already expect proposals for solutions, thus saving costs.

How has the feedback from your customers been since you started working with UBIK?

At the moment, customers don’t have that much contact with the tele-roofing itself, as most of it takes place in the background and the finished test report including the checklists is currently being sent to the customer.

How satisfied are you with our support?

Very satisfied. We always respond quickly to short-term enquiries. When it comes to larger construction sites, a quick solution is usually sought with great endeavour.

In general, the employees are always friendly and endeavour to resolve any problems, requests, etc. as quickly as possible to our complete satisfaction as quickly as possible.

Were there situations in which you needed support and how did you respond?

There have often been issues here where we have urgently needed support from the Augmensys team. This was always tackled immediately and clarified and resolved independently with the interface programmes of our software. The flow of information and feedback always reached us very quickly and was always very constructive and characterised by complete transparency.

Do you have plans to expand or change the inspection processes in the future?

We are in constant dialogue with Augmensys to further improve our product and implement new features. There are also other areas in which we are currently in dialogue. Here we benefit greatly from the ideas and suggestions from the Augmensys team that supports us.

Can you recommend, working with Augmensys?

In general, I can highly recommend working with Augmensys.

All requests, complaints and problems are dealt with immediately and we receive feedback or a proposed solution for each individual point within a very short period of time.

We also benefit greatly from the expertise of Augmensys for other exciting inspection processes for further implementations and improvements.

Recent Comments