UBIK® GO release: .NET MAUI client and modernized UI

UBIK® GO release: .NET MAUI client and modernized UI

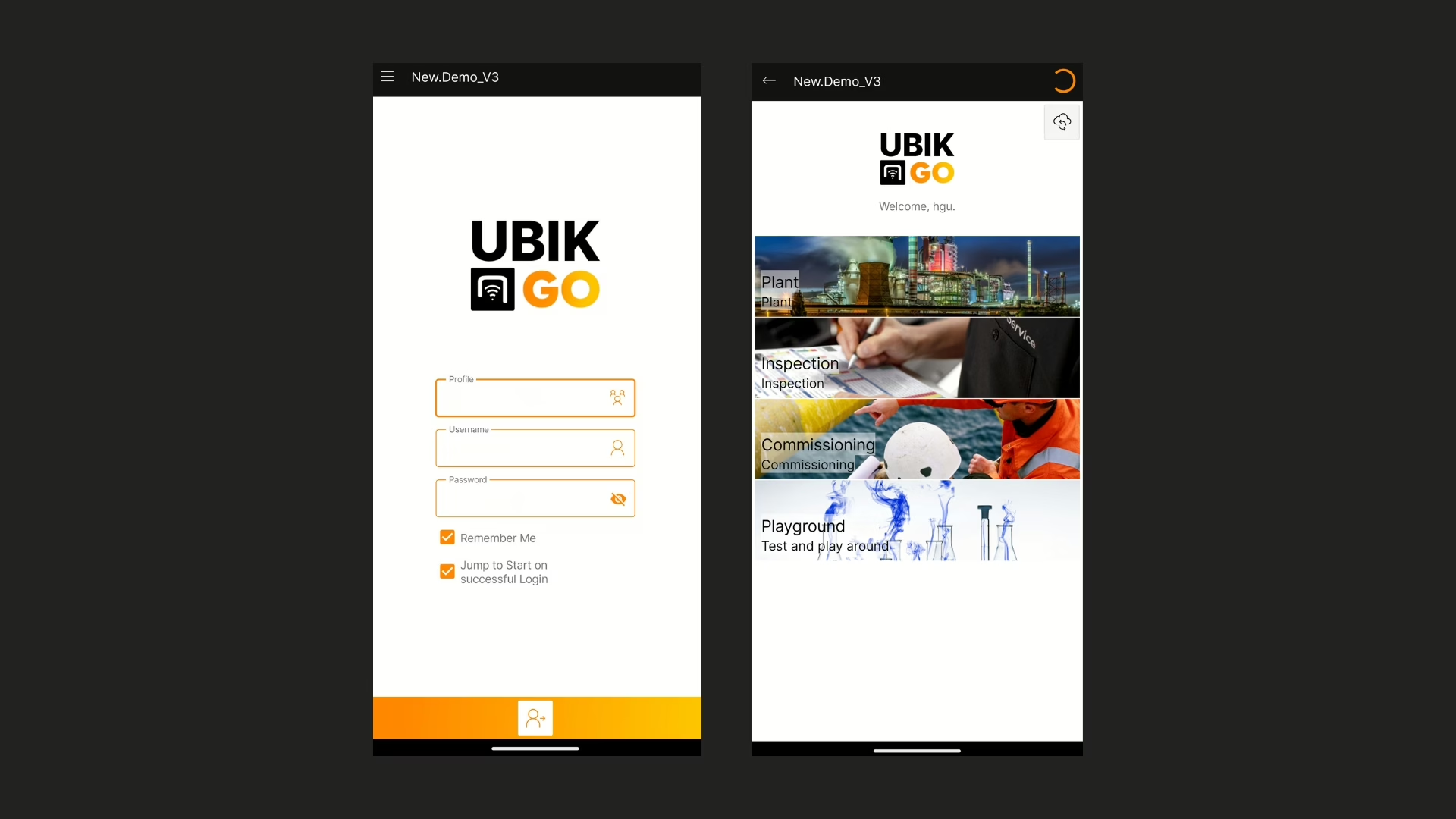

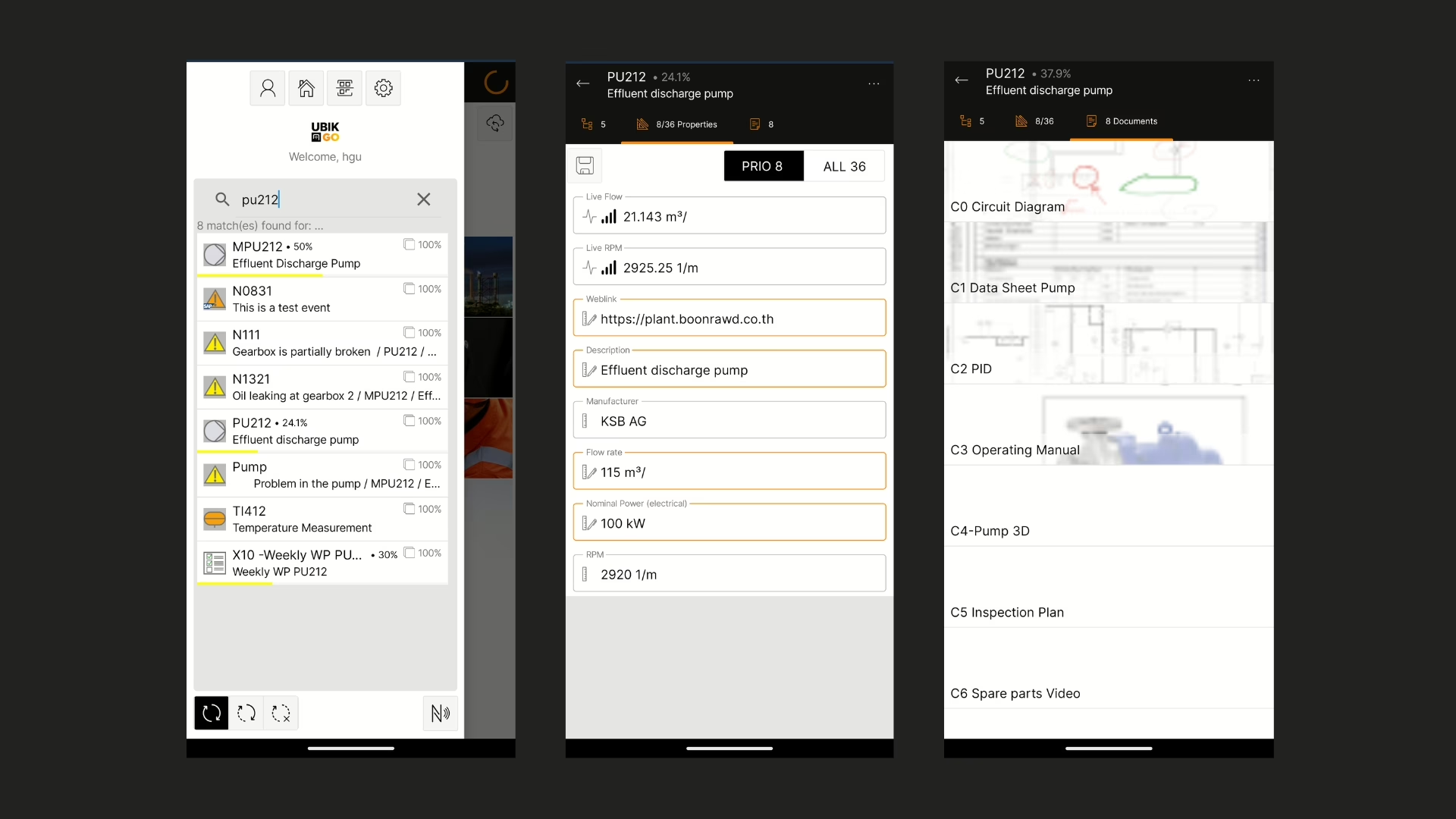

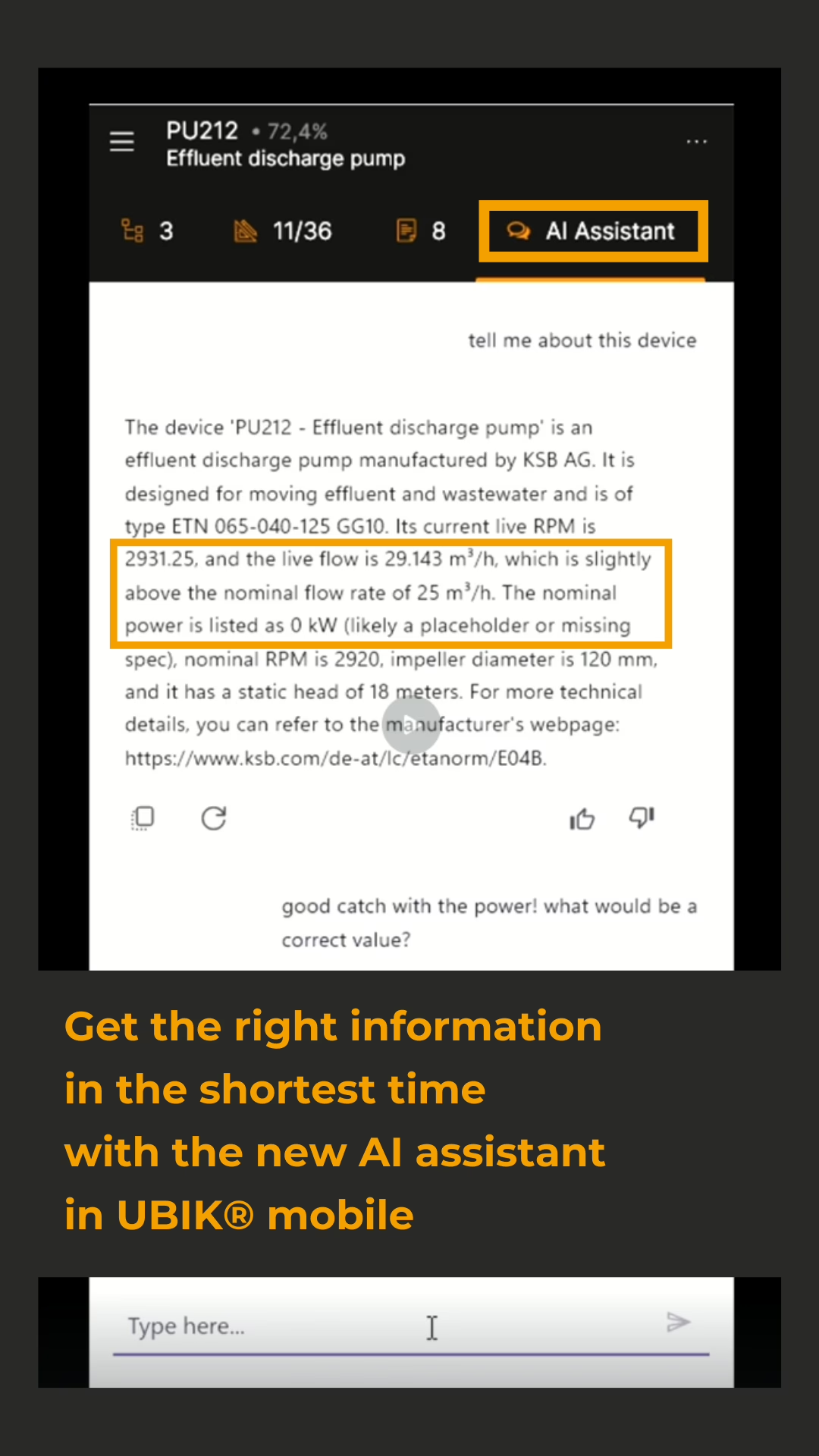

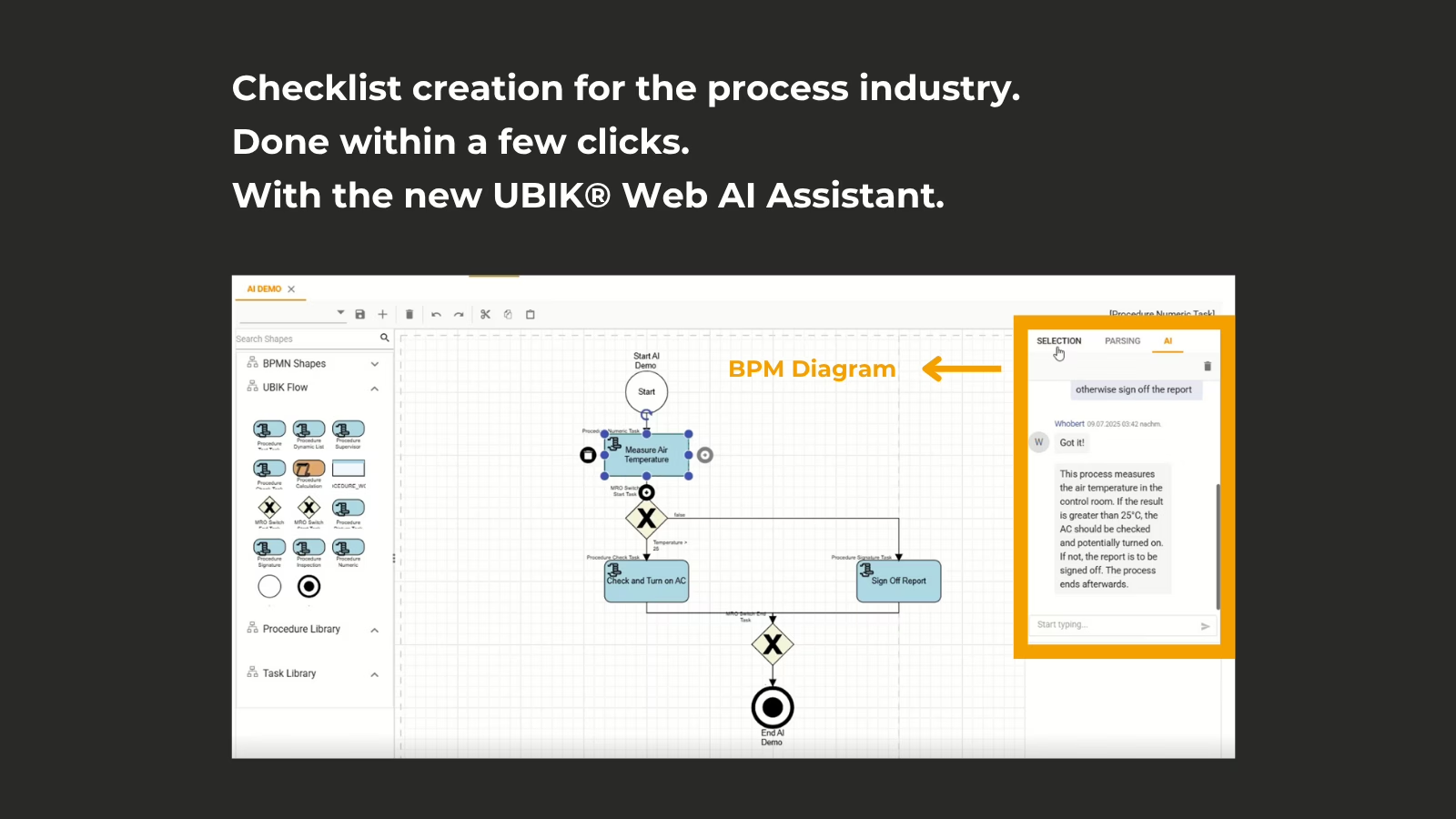

UBIK® GO is the fifth version of our proven industrial mobile software solution UBIK® and was developed specifically for industrial companies. A modern architecture developed from ground up offers employees in demanding environments unparalleled flexibility and performance.

With UBIK® GO, every application scenario, whether inspection, maintenance, commissioning or downtime management, can be carried out directly on your mobile device: securely, tailored to the needs of your company and fully functional even without a network connection.

The software integrates industrial data from various source systems, such as SAP or OPC, and brings it together seamlessly and in real time for efficient use. Proven features from previous UBIK® versions have been retained. At the same time, higher speed, scalability and offline reliability have been introduced.

A quick overview over the 5th iteration of UBIK®

-

New .NET MAUI client replacing Xamarin for long-term support and enhanced security

-

Modernized user interface

-

Foundation for future feature expansions in upcoming releases

A new name.

The name UBIK® GO represents the fifth major version of our software. The “GO” in the name comes from the Japanese word for “five”, emphasising the platform’s ongoing evolution and readiness for future improvements.

A new client.

The previous UBIK® versions were built on the Xamarin client, which has reliably served users for years, but with Microsoft ending support for Xamarin, migrating to .NET MAUI was necessary.

Key advantages of .NET MAUI:

-

Enhanced security:

-

reduced exposure to potential threats

-

-

Long-term support from Microsoft:

-

ensures maintainability and alignment with supported technologies

-

-

Improved performance and responsiveness:

-

lays the foundation for a faster and more efficient user experience

-

This migration future-proofs the solution, providing a solid base for both current users and upcoming updates.

A modernized UI.

UBIK® GO also features an updated UI compared to previous versions. The UI has been designed to enhance usability, particularly for field workers.

The app can now be customised to switch to dark mode. Previous roadblocks that prevented a custom dark UI have been removed.

Summary

With UBIK® GO, we have:

- Introduced a new name reflecting the fifth major iteration of the platform

- Replaced the Xamarin client with a new .NET MAUI client

- Introduced a modernized UI

- Built a solid foundation for future feature enhancements

UBIK® GO provides a supported, secure, and maintainable platform, allowing users to continue workflows reliably while enjoying a updated interface. The update provides a sustainable software solution for future developments.

Find the details and specific changes for each mobile and desktop version on our Wiki pages:

Recent Comments