UBIK and the HoloLens

Admittedly, the combination of UBIK® and Hololens® does not seem to be very reasonable at first glance. Especially because we promote solutions for industrial applications, that work even under the harshest conditions.

The HoloLens® is surely labelled with many attributes these days, but industry-proof is hardly among them.

The second glance

However, on a second glance, it looks a bit different. Firstly, there are areas or periods in the plant-lifecycle that don’t require special certifications such as ATEX etc., even in the process-industry, which can be defined as our core-industry. Secondly, the past year also marked a broadening of our clientele beyond the process-industry and today we also count companies from mechanical-engineering and automotive-supply-industries among our customers. And last but not least, we just recently switched our Windows client to the new Universal Windows platform (UWP), which is also the basis for Hololens applications.

Strengths and weaknesses

It turned out that there are enough reasons to take a closer look at Hololens- and this is exactly what we started a few months ago. The first tests were quite impressive, especially the environmental mapping is to be emphasized. That’s already pretty nice on its own, but at the status quo there isn’t a real customer benefit. After all, everything the user can do (e.g. placing applications or holograms in the room) is designed to work within a very limited radius around him, and also tied to the WiFi router – let’s face it, neither the radii are restricted in our plants (actually its quite the opposite) nor can we rely on WiFi, because most of the time the user works completely offline.

The combination

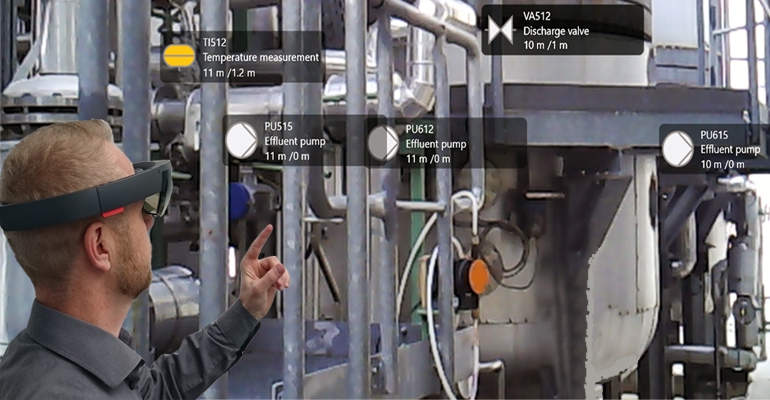

But if one combines what the HoloLens can do well, namely tracking at close range, with the information UBIK already provides, a number of productive applications emerge immediately.

UBIK usually knows the complete data model of a system and often the objects within are already tagged with absolute position information (geo-data). UBIK objects and structures also have the profitable ability to hold an arbitrary amount of additional information, and that could also be the mapping information generated by the Hololens, the so-called Spaces.

Now, UBIK could take over the rough positioning on the Hololens, which is already done today through GPS/sensors or geographic markers. With this information, the Hololens will automatically be supplied with the respective relevant space and will therefore be able to fully exploit its strengths at close range. The result? The closer the user moves to his target object, the more accurate the tracking will be, just as it should be; and the positive side effect: the Hololens is suddenly fully offline-capable, because it takes advantage of all features of the UBIK platform.

How far away we are from that? Not far, stay tuned and be surprised!

Termine

3. VDI Fachkonferenz

6. – 7. September 2018, München

…Augmented und Virtual Reality als Smart Assistance

Chemical Enterprise 4.0

29. November 2017

… Digitalisierung in der Chemieindustrie

Standorte

Augmensys

Desenvolvimento de Software Ltda

Rua Lanciano, 60, Jardim Suzana

São Paulo 04784-190 | Brasilien

Augmensys

Desenvolvimento de Software Ltda

Rua Lanciano, 60, Jardim Suzana

São Paulo 04784-190 | Brasilien

USEFUL LINKS

Termine

3. VDI Fachkonferenz

6. – 7. September 2018, München

…Augmented und Virtual Reality als Smart Assistance

Chemical Enterprise 4.0

29. November 2017

… Digitalisierung in der Chemieindustrie

Standorte

Augmensys

Desenvolvimento de Software Ltda

Rua Lanciano, 60, Jardim Suzana

São Paulo 04784-190 | Brasilien